WHEELS

for bridge cranes

The bridge crane is certainly one of the most popular lifting and transport equipment in the industrial sector.

We cannot think of a steel plant or a park for raw materials or a cement plant not equipped with an overhead crane.

Regardless of the size of the slow or fast bridge cranes, the problem to be emphasized is the efficiency and durability of the wheels.

The wheels for bridge cranes are an element of fundamental importance. In fact, they must not only ensure maneuverability but guarantee a high degree of safety and efficiency over time.

After years of experience in the production of monobloc wheels for "high speed" trains at the main Italian manufacturer, the technology has been transfused in the production of overhead crane wheels at our company.

The wheels are produced using a specially designed quality steel and a particular hardening process.

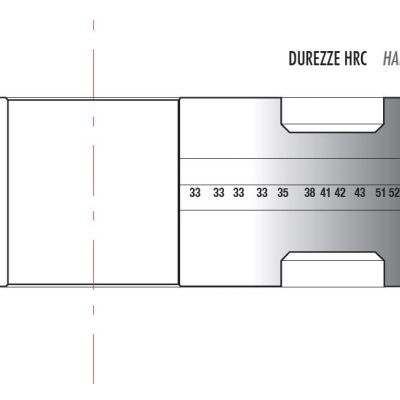

The material in the hardened and stretched state "in the hardened zone" of the rolling thus has a predominantly martensitic structure whose hardness extends for a depth from 15mm to 25mm which cannot be obtained with traditional procedures such as induction hardening, flaming etc. .

The wheels are machined to design and the shafts can be shrink-fit on request.

The advantages of our wheels thanks to the quality of the steel and the particular hardening treatment are:

an excellent depth of hardness is guaranteed with a consequent reduction in wear and therefore an increase in service life. The gradient given by the heat treatment ensures excellent toughness to the hub

the rolling surface thanks to the treatment is placed in compression ensuring the non-initiation and propagation of cracks (they are called "indefatigable")

near the hub, a metallurgical structure is observed which guarantees considerable toughness